January 23, 2024

SPOTLIGHT ON: Wash Testing and Wash Testing Consumables

The Importance of Wash Testing

A fundamental question that needs to be answered before consumer textile products are approved for sale to the public is, how will they perform once the customer launders them? There is an expectation from the consumer as to what they would expect post washing. Significant changes to garments would not be tolerated and would lead to products being returned to retailers, poor reviews, loss of revenue and brand/reputation damage.

What may seem a relatively simple thing to test is actually quite a complex and multifaceted set of challenges for the labs and retailers to adequately evaluate. First, there is the variability is how each individual customer washes their clothes. Factors could include: frequency, temperature, color separations, load size, washing machine type, detergent type, how they dry the product, etc. This creates a moving target for the retailers to best understand how their products will perform during home laundering. If we consider what a retailer will actually evaluate during product wash evaluation, we can show how the standards are developed to try and minimize the variables and give the retailer the best chance at understanding how their products will perform.

To assist in determining the best way to standardize the testing, garment care instructions are taken in to account. Most retailers will specify that domestic laundering tests are performed at care label temperature, and if it can be tumble dried then, this is chosen as the drying method, as this would be the most ‘severe’ test permitted in line with the care instructions. Some retailers also go the extra step of testing at 10°C above care instructions to account for customers who may choose to wash in water hotter than recommended. There are a lot of 30°C care instructions now, as the trend for home laundering is to wash at lower temperatures, however, a significant number of customers will still choose 40°C water as they believe it cleans the clothes more thoroughly.

Different Types of Wash Tests

Dimensional Stability Testing

This is often called the shrinkage test, but this a misunderstanding. Dimensional stability refers to any change in the products dimensions during washing/cleaning so we must also consider whether the product has grown as well as shrunk – typically seen in knitted and true knitwear items. Also, other observations can be made such as Bow and Skew – where the straight yarns crossing the fabric perpendicular to the width can be distorted causing visible slant in the yarns from one side to the other (skew) or a visible curve of the yarns between the two edges (bow). Also, spirality can be evident in knitted garments where the side seam seemingly starts to twist around the bottom of the garment. This is usually caused by unbalanced yarns being used in single jersey items.

Promotional Claim Validation

This is not just important for the retailer to evaluate whether their claim is true, it is also required for legality of the claim. Retailers are not legally permitted under consumer law to make false performance claims. Examples of such claims could be - improved color retention, permanent creases, improved stain release, durable water-resistant finishes, Hi-Viz durability, etc.

All of these claims would need to be tested and benchmarked against the products which they claim to be ‘better’ than. The results would then be then be retained should any customer complaints be raised to trading standards or similar bodies.

After Wash Appearance

As well as the dimensional change in the garment or fabric, retailers are also interested in how the garment looks after multiple washes. Typically, they will make an assessment after 1 wash, 5, washes, and 10 washes or a similar routine of increasing number of washes. They want to be able to understand how the surface of the fabric performs over time. They may look for color loss, pilling/fuzzing of the fabric, cross staining, creasing, how any trims or embellishments have performed or remained attached. At each wash point a full set of assessments will be done. This can overlap with any work being done to validate promotional claims, as above.

Preparatory Washes for Subsequent Testing

Not all washes are done to reach an end point of the test. Some washes are performed as a preparatory step for a different test. Examples of this are flammability testing and various pilling methods.

Wash Testing Equipment and Consumables

Wash Testing Equipment and Consumables

So, with everything that a wash test can tell the retailer, it is important that these tests are performed under standard conditions to ensure consistency and repeatability in results. To do this several parameters are defined in the various international standards for dimensional stability to washing/home laundering. Components include:

- Washing Machine Types – Vertical Axis, Top Loading Machines such as the Vortex M6 or Horizontal Axis, Front Loading Machines such as the Wascator CLS. These machines are heavily standardized. Every functional parameter is defined in the international standard from the physical dimensions of the machine and drum, to how the machines control the wash programs. Any machine used for these standardized tests must comply with these parameters.

The most commonly used lab machines such as the Vortex M6 and Wascator CLS are programmable and therefore have an element of future proofing as the standards change to reflect the washing trends seen in home laundering, things like lower agitation, low liquor volumes and lower temperatures.

- Drying Equipment - Vortex M6D, and The Precision Tumble Dryer. Like the previous, these instruments are fully specified in the international standards from drum size, size and number of lifting vanes, drying rate etc. Again, the labs choose programmable equipment to future proof any changes in the standards and to increase versatility

Detergents Consumers have a vast array of options in detergent choice – low temperature optimized, with or without optical brighteners, with or without enzymes, with or without softeners, so it can be difficult to standardize detergent use. Additionally, there are detergent formulations which are more common in certain geographical regions such as AATCC reference detergent for the Americas, IEC and ECE variants for the European market, JIS detergent for the Japanese market and specialized liquid detergents for delicate items.

Detergents Consumers have a vast array of options in detergent choice – low temperature optimized, with or without optical brighteners, with or without enzymes, with or without softeners, so it can be difficult to standardize detergent use. Additionally, there are detergent formulations which are more common in certain geographical regions such as AATCC reference detergent for the Americas, IEC and ECE variants for the European market, JIS detergent for the Japanese market and specialized liquid detergents for delicate items.

What all of these reference detergents have in common is that they are designed to be REPRESENTATIVE of the consumer detergents, but not REPLICATATIVE. It is not possible for one or two reference detergents to be identical to the whole gamut of commercial products available. During standard revisions, it is part of the process for the committee to consider whether these formulations are still relevant and whether they may need adjustment as commercial detergent formulations change.

What all of these reference detergents have in common is that they are designed to be REPRESENTATIVE of the consumer detergents, but not REPLICATATIVE. It is not possible for one or two reference detergents to be identical to the whole gamut of commercial products available. During standard revisions, it is part of the process for the committee to consider whether these formulations are still relevant and whether they may need adjustment as commercial detergent formulations change.

An example of a change which was implemented due to the formulations no longer being representative can be seen by the removal of ECE B and AATCC Detergent with Phosphates from the ISO 6330:2001 standard revision onwards. During the years between the 1994 standard and the 2001 revision, the commercial detergent producers removed phosphates from their products. Phosphates had long been used to improve the efficiency of the detergent, but once they pass through the washing machine and out in to the waste water, they can find themselves in aquatic systems where they behave as a fertilizer for micro plants, such as algae. These ‘Algal Blooms’ blanket the surface of the water and starve the organisms below of light and oxygen. Their removal from domestic detergents was reflected by their removal from the home laundering standards.

More recently there is an example of where a detergent formulation amendment was made, but also the original formulation was left in place as an alternative. In the IEC and ECE detergents Sodium Perborate Tetrahydrate is used as the bleaching agent. In home laundering its use was banned or restricted many years ago in many countries with the US and Germany as examples of countries which outlawed its use a long time ago. Used in many products, from detergents to cosmetic items, it is a source of hydrogen peroxide and when used in conjunction with a low temperature bleach activator it is a suitable bleaching agent for detergents. However, the chemical itself has toxicity problems and is on the REACH list for Europe. In 2021, to recognize the trend of consumer detergent moving away from Sodium Perborate, Sodium Percarbonate was listed as an alternative bleaching agent in ISO 6330:2021. This reflects the change in commercial detergent, but because both Perborate and Percarbonate are used as a source of hydrogen peroxide, both are considered equally representative of a domestic detergent, even though domestic detergent no longer contains Perborates.

More recently there is an example of where a detergent formulation amendment was made, but also the original formulation was left in place as an alternative. In the IEC and ECE detergents Sodium Perborate Tetrahydrate is used as the bleaching agent. In home laundering its use was banned or restricted many years ago in many countries with the US and Germany as examples of countries which outlawed its use a long time ago. Used in many products, from detergents to cosmetic items, it is a source of hydrogen peroxide and when used in conjunction with a low temperature bleach activator it is a suitable bleaching agent for detergents. However, the chemical itself has toxicity problems and is on the REACH list for Europe. In 2021, to recognize the trend of consumer detergent moving away from Sodium Perborate, Sodium Percarbonate was listed as an alternative bleaching agent in ISO 6330:2021. This reflects the change in commercial detergent, but because both Perborate and Percarbonate are used as a source of hydrogen peroxide, both are considered equally representative of a domestic detergent, even though domestic detergent no longer contains Perborates.

Wash Ballasts In a home laundering environment, it is very rare for an item to be washed alone. More often it will be washed together with numerous other items up to the capacity of the machine being used. The other items actually have an influence on how the items performs during the wash cycle. In a scenario where one item is washed alone, then agitation, liquor interaction, abrasion will all be different, and likely be misrepresentative when compared to a home laundering cycle. To compensate for this and to do so in a standardized way, the use of Ballast is required in the standards for dimensional stability, and most other after wash performance methods.

Wash Ballasts In a home laundering environment, it is very rare for an item to be washed alone. More often it will be washed together with numerous other items up to the capacity of the machine being used. The other items actually have an influence on how the items performs during the wash cycle. In a scenario where one item is washed alone, then agitation, liquor interaction, abrasion will all be different, and likely be misrepresentative when compared to a home laundering cycle. To compensate for this and to do so in a standardized way, the use of Ballast is required in the standards for dimensional stability, and most other after wash performance methods.

Sometimes also known as Makeweights, or Dummy load, in the ISO 6330 standard there are 3 ballasts defined. Which one you choose depends on the composition of the product(s) you are testing. But they are all used to make the test load up to 2.0 ± 0.2kg. This consistent load weight will create a consistent level of agitation from one wash to the next and reduce the variability associated with reduced or increased load sizes. There are numerous other ballasts associated with other home laundering standards. The AATCC specifies 3 different types of ballast too, they differ from the ISO ballasts in several ways, and should not be used interchangeably, but they serve the same purpose and are used to make a load size of typically 1.8 ±0.1kg.

How are results interpreted?

Retailers and manufacturers will collect all of the numerous pieces of information they get from these home laundering tests and either approve, reject or create correction actions to improve and retest. Retailers set the tolerances for what they are prepared to accept. For instance, no product would be expected to have zero dimensional changes after washing and what is acceptable will depend on what the product is made from – cotton may shrink more than polyester for example.

There is a larger tolerance for knitted garments compared to woven as knitted products are inherently less dimensionally stable, especially Single Jersey construction.

It could also depend on the end use. 5% shrinkage may not be acceptable in Slim Fit Shirt, but would barely be noticeable in a flowing Maxi-Dress.

If a manufacturer sees high shrinkage, then perhaps they can set the fabric better in finishing, if they see high color change then they can look at dye selection and the fixation or clearing processes.

If a retailer sees high shrinkage, which cannot be improved then they could look at an alternative material or creating an appropriate set of care instructions so the issue will not be seen by the customer, the same would also minimize excessive color losses where no improvement can be made.

The home laundering tests are extremely important to the manufacturer and the retailer, but they must be performed in as controlled a way as possible.

Frequently asked Questions about Wash Testing Consumables

What is the difference between ECE and IEC?

The IEC is the International Electrotechnical Commission. This is a standards organization which publishes standards for the electrotechnical sector. The detergents they specify would be used by manufacturers of laundering equipment to validate their performance.

ECE is the European Colorfastness Establishment, which in cooperation with ISO are responsible for color fastness standards, and their detergent are used in these standards.

In reality the detergents themselves are very similar to each other.

To think about it simply…

-

Any detergent called ‘A’ is non-phosphate.

-

Any detergent called ‘B’ contains phosphate.

-

Any IEC detergent contains OBA

-

Any ECE detergent is OBA free

So, for example, ECE A and IEC A are essentially identical apart from IEC A has OBA.

The IEC also have a formulation for detergent with a protease enzyme too, this is IEC A*. This is most representative of a commercially available biological detergent.

What is TAED?

TAED (tetraacetylethylenediamine) is a low temperature bleach activator used in European markets. It creates an oxidative bleaching system with Perborate and Percarbonate at lower temperatures than either would normally readily evolve Hydrogen Peroxide. It is not used in the US, where NOBS (SNOBS) is the preferred low temperature bleach activator.

The IEC/ECE detergents you see do not contain Perborate/Percarbonate or TAED. Why?

If the perborate/percarbonate and TAED were mixed in to the detergent then they would react together over time (especially in hot countries with high humidity) and the bleaching potential of the detergent would degrade, severely reducing the shelf life of the products. Adding them separately just before testing preserves chemical activity and shelf life.

Why is ECE B offered, despite not used in any home laundering methods since 2001.

ECE B is still used in ISO 105-C06:2010, which is the color fastness to domestic and commercial laundering standard. AATCC reference detergent WOB is also used in this standard, but outside of the Americas the ECE B is more common.

What products do SDL Atlas Supply for Wash Testing?

403657 AATCC Standard Reference Detergent (With Optical Brightener) – 7.3 kg

403658 AATCC Standard Reference Detergent (WOB) – 7.3

400652 IEC Non-Phosphate Standard Reference Detergent A*

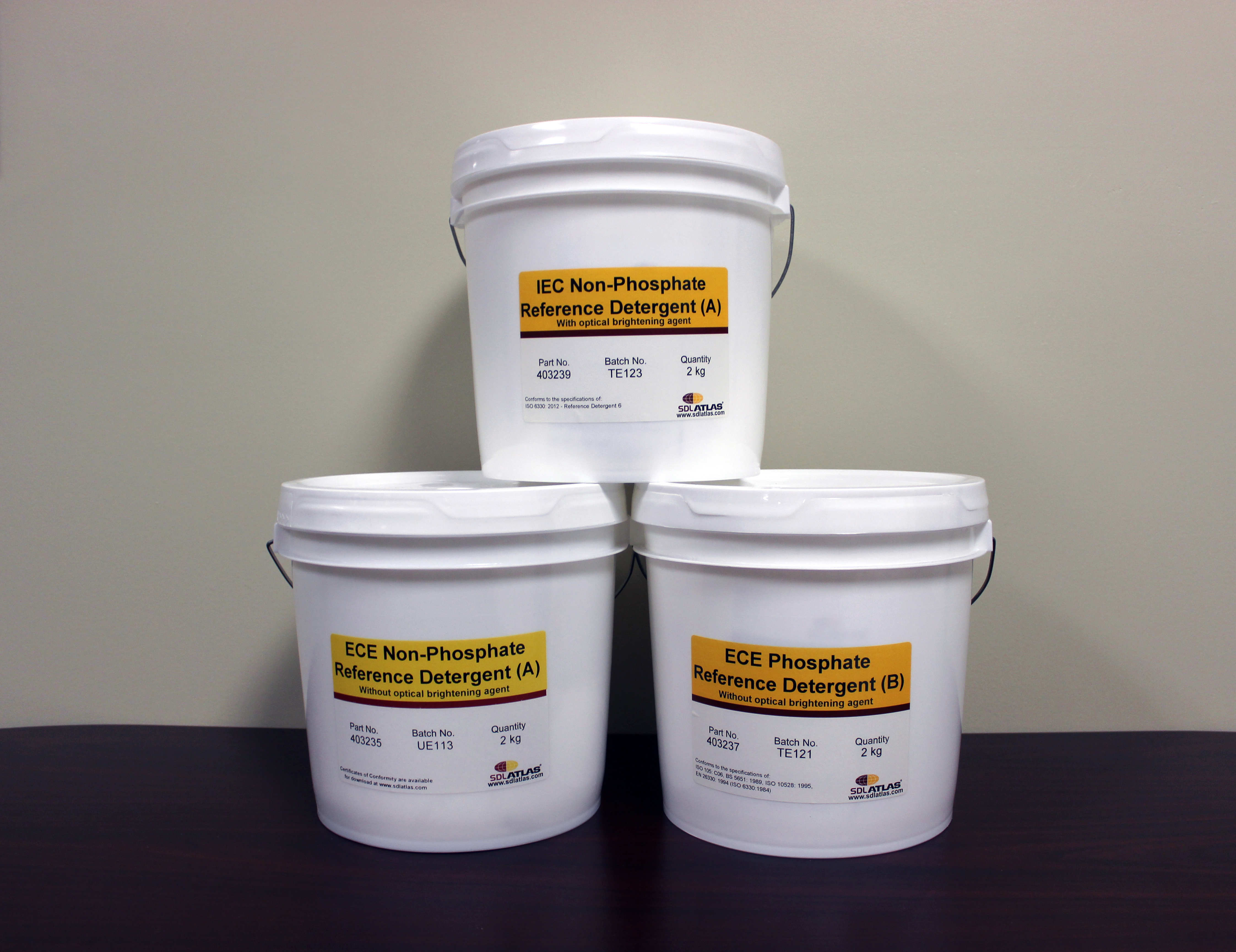

403235 ECE Non-Phosphate Standard Reference Detergent A - 2kg

403236 ECE Non-Phosphate Standard Reference Detergent A - 15kg

403237 ECE Phosphate Standard Reference Detergent B - 2kg

403238 ECE Phosphate Standard Reference Detergent B - 15kg

403239 IEC Non-Phosphate Standard Reference Detergent A - 2kg

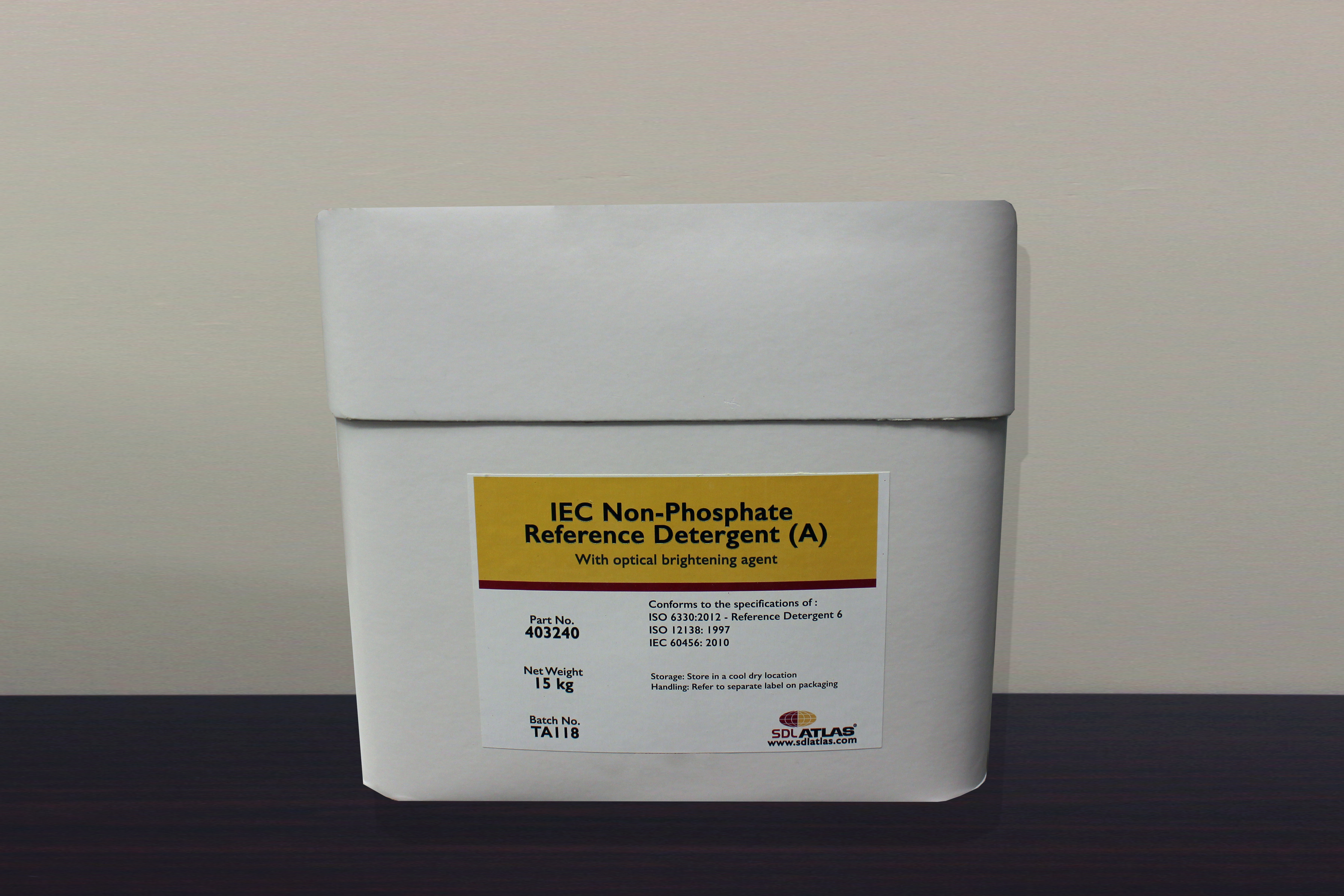

403240 IEC Non-Phosphate Standard Reference Detergent A - 15kg

403738 (SDL) IEC-W Liquid Reference Detergent - 1L

403720 (SDL) PRINT TEST Durability Detergent - 5Kg (for Next approved lab only)

403408 Tetra-acetylethylenediamine (TAED) - 90-94% Activity

300855 Sodium Perborate Tetrahydrate - 2kg

202161 AATCC Gray Scale for Assessing Staining

202162 AATCC Gray Scale for Assessing Color Change

403231 ISO Grey Scale for Assessing Color Change

403232 ISO Grey Scale for Assessing Staining

401357 AATCC Cotton Ballast - Type 1

401359 AATCC Polyester/Cotton Ballast - Type 3

203709 ISO Cotton Ballast - Type I

203710 ISO Polyester/Cotton Ballast - Type II

403468 ISO Polyester Ballast – Type III

403386 AHAM Cotton Ballast

403380 UL Cotton Ballast