August 22, 2023

SPOTLIGHT ON: SDL ATLAS ABRADANT FABRIC

Martindale Abrasive Fabric – A Brief History

In the 1940’s Dr. J. G. Martindale was working for The Wool Industries Research Association (WIRA) on a machine which could help to test the abrasion resistance of a material produced to protect against gas attacks during World War II. The machine he developed took the Martindale name, and has been virtually unchanged in the almost 80 years since. The Martindale, for testing abrasion resistance, is now used to test an extensive list of materials, from general apparel, PPE, firefighter uniforms, racing suits, to car and home upholstery and beyond.

To be able to determine the abrasion resistance of a fabric, the Martindale is only part of the equation. You need an ‘abradant’ which is going to be more durable than any fabric which you would wish to test. If the abradant is destroyed by the test specimen, then you cannot determine the actual durability or more importantly how ‘fit for purpose’ your test specimen will be in the real world.

To find such an abradant in the 1940’s would have been a tough task. Synthetic fibers, with controllable fiber diameters and high durability were in their infancy, in fact only Rayon had been available commercially until Nylon was introduced in the late 1940’s. This left a choice of the typical natural fibers. No one seems to know exactly how the Wool Abradant we all know today became the cloth of choice in the 1940’s. There is a nice story that Dr. Martindale actually stumbled upon the cloth when looking inside his neck tie, which was stiffened by a lining of a Worsted Wool cloth. He sourced some of this cloth on the roll… and the rest is history.

The Martindale Abrasive Fabric is a Worsted Wool Fabric, which is incredibly durable. With the advent of standardization, the cloth now has to meet numerous specifications in order to ensure that the cloth’s properties remain consistent from batch to batch. A standardized abradant needs to be repeatably abrasive so that the manufacturers of the products being tested get reliable results in order to make sure that their performance requirements are being met.

How is Abrasive Fabric used?

The abrasive fabric is used in conjunction with the Martindale Abrasion Tester. It is placed on the static abrading table of the Martindale, pressed down with a weight and locked in to position, leaving a flat and consistently taut surface of cloth, against which the specimen will be abraded. The abrasive fabric is always placed over a layer of standardized woven or nonwoven felt which provides a layer of cushioning underneath the abrasive cloth. This is to simulate more closely the conditions which the test specimen would experience in the real world.

The abrasive fabric is used in conjunction with the Martindale Abrasion Tester. It is placed on the static abrading table of the Martindale, pressed down with a weight and locked in to position, leaving a flat and consistently taut surface of cloth, against which the specimen will be abraded. The abrasive fabric is always placed over a layer of standardized woven or nonwoven felt which provides a layer of cushioning underneath the abrasive cloth. This is to simulate more closely the conditions which the test specimen would experience in the real world.

The test specimen is placed in the Martindale specimen holder, usually cushioned by a layer of standardized foam, in such a way that the tension and smoothness of the surface is repeatable. The face of the test specimen is then placed against the face of the abrasive cloth at either a pressure of 9 kPa or 12 kPa depending on the end use of the test specimen. The Martindale then ‘rubs’ the test specimen and abrasive fabric together in a Lissajous pattern.

The Lissajous pattern gives a completely even wear on the test specimen’s surface to avoid any wear which could be unrealistically one dimensional in the real world. The Lissajous figure is created by rotating drive pins to produce two simultaneous motions working perpendicular to each other, this creates a movement which changes from a circle to gradually narrowing ellipses, until it becomes a straight line, from which progressively widening ellipses, develop, in a diagonally opposite direction before the pattern is repeated. Each complete Lissajous equates to 16 ‘rubs’ and traces around 3 m of distance. The Martindale abrasion head assembly is also able to freely rotate around its axis to ensure the rubbing motion is completely uniform.

The Lissajous pattern gives a completely even wear on the test specimen’s surface to avoid any wear which could be unrealistically one dimensional in the real world. The Lissajous figure is created by rotating drive pins to produce two simultaneous motions working perpendicular to each other, this creates a movement which changes from a circle to gradually narrowing ellipses, until it becomes a straight line, from which progressively widening ellipses, develop, in a diagonally opposite direction before the pattern is repeated. Each complete Lissajous equates to 16 ‘rubs’ and traces around 3 m of distance. The Martindale abrasion head assembly is also able to freely rotate around its axis to ensure the rubbing motion is completely uniform.

The test specimen is inspected, using a light and magnifying glass, after a number of ‘rubs’, and this process is repeated until the test specimen is deemed to have broken down, this is determined by one of the criteria for breakdown being met. At this point the test can end. The criteria for breakdown are listed in ISO 12947-2 and ASTM D4966.

As a general rule the test can end when…

- One thread is broken for a knitted fabric.

- Two threads are broken for a woven fabric.

- Pile or Flock is completely worn off.

- A change of shade is observed which would lead to complaint.

- A hole appears for a nonwoven.

Note – the actual end point, in number of rubs, is determined by the average of testing at least 3 different specimens from the same test sample.

How are results interpreted?

In the case of an abrasion test, the results are easy to interpret. The higher the number of rubs taken to break down the test specimen, the more durable the specimen is.

In the case of an abrasion test, the results are easy to interpret. The higher the number of rubs taken to break down the test specimen, the more durable the specimen is.

Retailers and manufacturers will have different requirements for durability depending on the end use of their fabric or product. Items which would be expected to encounter low abrasion in their day to day use would have a lower durability requirement than a product which would be expected to encounter high wear or abrasion. For example, a fabric which is going to be used for a woven fashion shirt may only need to be durable for 20000 rubs, where as a woven fabric made for a corporate workwear uniform shirt may be expected to last for over 50000 rubs. This is due to the nature of the work the wearer could be doing, or just due to the fact that a uniform is likely to be worn many more times than a fashion piece.

Similarly, apparel items may only be tested with a pressure of 9 kPa, and a fabric for PPE or Upholstery will be tested to 12 kPa pressure, to reflect their respective end uses.

But as a rule, for 2 fabrics with the same end use, tested under the same conditions, the one with the highest number of rubs at breakdown is the most resistant to abrasion.

These required minimum breakdown values are linked to years of experience in producing a particular cloth for a particular end use. They are hard to convert in to a ‘time’. So, we cannot say, for example, that 20000 rubs are equal to 2 years of use, because frequency and type of use is impossible to predict. The values are a benchmark for products which have achieved the minimum standard and no complaints or fundamental failures have been reported in the real world. They give the retailer/manufacturer confidence that the product will be fit for purpose. If a product did receive complaints of premature wear then it would trigger an investigation.

Who are the potential customers for the Martindale Abrasive Fabric?

The Martindale is one of the most common textile testing instruments in the world. Even the smallest of internal mill laboratories will often have a Martindale.

- Customers making woven or nonwoven materials will be more interested in abrasion resistance than those producing knitted products, but actually in the ISO standard there are requirements for all of these.

- Independent test labs

- Anyone who uses woven felt and foam

Frequently asked questions about Abradant Fabric

Is ‘SM25’ Abrasive Fabric different than the Abradant Fabric SDL Atlas supplies?

You may have heard the designation SM25 in reference to Abrasive Fabric. SM25 was simply just a reference number used by Woolmark Company when they first developed their abrasion test methods. SM25 was the designation assigned to the abrasive fabric that they used that was compliant to ISO 12947-1. For more context, in the Woolmark Test Method 112 Abrasion Test Standard, the abrasive cloth was referred to as SM25, the standard woven felt was referred to as SM26 and the standard foam was referred to as SM28.

SDL Atlas Abrasive Fabric is FULLY compliant with the same requirements as ISO 12947-1, just as SM25. So rather than a specific type of Abrasive Fabric, SM25 is simply a designation that the industry used for a while rather than the generic term.

Wool is a natural product. How can we know it will perform the same for every batch?

First, the cloth is specified right down to the fiber diameter of the wool used to make it. There are numerous requirements we have to meet to ensure the cloth is structurally the same each time. SDL Atlas does independent testing, at a UKAS lab approved to ISO 17025, for the yarn and the cloth. If there is a non-compliance the cloth is rejected.

Second, we check the abrasive properties of EVERY ROLL of cloth we produce. This is done on a Martindale abrasion tester, using a test fabric of known breakdown. SDL Atlas also has a Master batch of abradant which came from our first ever fully approved batch. The abrasion results for each roll are statistically analyzed and any rolls which are outliers are rejected.

No customer has EVER rejected SDL Atlas Abrasive Fabric for compliance concerns.

Does SDL Atlas supply all of the complementary materials, such as the felt and foam?

Yes! We have a comprehensive range of materials for Martindale Abrasion Testing:

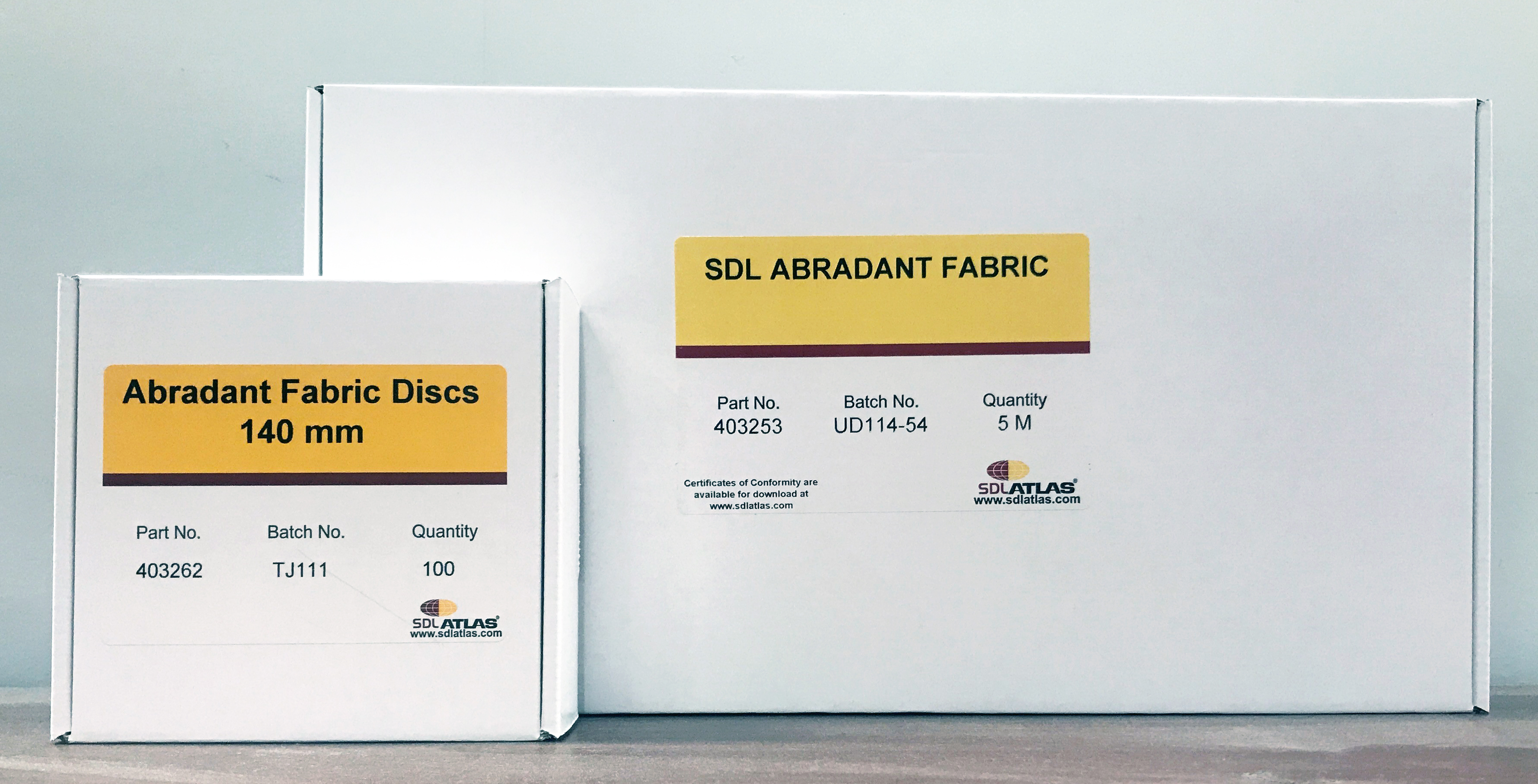

403253 Martindale Abrasive Cloth – 5 m Piece

403253 Martindale Abrasive Cloth – 5 m Piece- 403262 Martindale Abrasive Cloth 140 mm Precut Discs – 100 pieces

- 200947 Martindale Woven Felt – per meter

- 200971 Martindale Woven Felt 140 mm Precut Discs- 20 Pieces

- 200945 Martindale Nonwoven Felt – per meter

- 200946 Martindale Nonwoven Felt 140 mm Precut discs – 20 Pieces.

- 108179 Standard Martindale Backing Foam – 25 Sheets

For more information concerning SDL Atlas Martindale Consumables or any of our Textile Testing instruments, consumables or services, visit our website: www.sdlatlas.com.